To provide products of excellent quality, TSK implements an uncompromising inspection system.

In addition to general JIS testing, TSK can test products according to the standards of each country and other standards.

General Testing

-

1Appearance and Dimension Testing

Used forAP tubesBA tubes

- Measurement of length, outer diameter, wall thickness or inner diameter

- Measurements are performed using stringently managed and regularly calibrated micrometers, tape measures and calipers.

- Appearance inspection by eye

- Qualified, experienced inspectors perform 100% inspection of all aspects of each tube.

-

2Steel Grading

Used forAP tubesBA tubes

- Steel grading using handheld fluorescent X-ray spectrometers

- The equipment TSK uses can grade over 400 types of steel.

-

3Eddy Current Test

Used forAP tubesBA tubes

- 100% pass-or-fail grading according to industry standards or customer requirements

- When a magnetic field is created around a tube using electromagnets, eddy currents are generated in the tube. If the tube is scratched, the flow of the eddy current will change, altering the magnetic field. Detecting those changes enables scratches to be detected automatically.

-

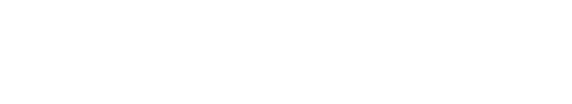

4Mechanical-property Test

Used forAP tubesBA tubes

- Test according to appropriate standards of mechanical properties such as tensile strength, proof stress, elongation and hardness

-

To measure mechanical properties, tension is applied until the tube breaks. A microhardness gauge is used to measure hardness.

Additional Tests

-

1Penetrant Test

Used forBA tubes

- Confirmation of defects open to the surface using penetrant and developing fluid

- When the tube surface is coated with penetrant, the penetrant seeps into the defects. After the penetrant is removed, developing fluid is applied. The residual penetrant in the defects seeps out and expands, enabling detection of tiny defects.

-

2Hydrostatic Test

Used forAP tubesBA tubes

- A pressure-resistance test according to customer requirements

- The tube is filled with water and held while the water is subjected to a specified pressure. Operators confirm whether the pipe breaks or not.

-

3Roughness Measurement

Used forBA tubes

- Measurement of roughness on the inner and outer surfaces using a roughness gauge

- The tube is tested with a surface roughness gauge to determine whether the roughness (presence of tiny protrusions and cavities) of its surfaces is above or below a certain number.

-

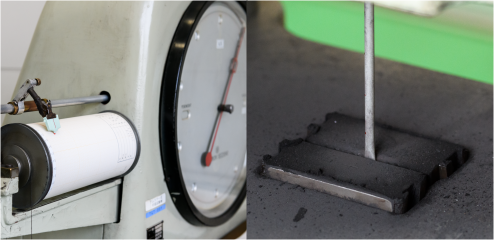

4Corrosion Test

Used forAP tubesBA tubes

- Confirmation that there is no intergranular corrosion and fracture

- After sensitization heat treatment, the tube is soaked for a specified time in an aqueous solution of boiled sulfuric acid and copper sulfate, then subjected to a bending test to determine whether it breaks or not.

-

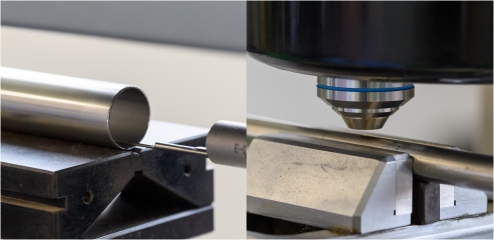

5Roundness Measurement

Used forAP tubesBA tubes

- Measurement of roundness according to customer requirements

- A product with a specified roundness tolerance is examined using a roundness gauge.

-

6Other

- Product and production-method development

- With the installation of a scanning electron microscope (SEM) and energy dispersive X-ray analyzer (EDX), TSK is developing exciting new products and production methods.